Main Keyword: Bluetooth PCB

Related Keywords: Bluetooth technology, Bluetooth standards, Bluetooth evolution, Bluetooth PCB applications, Bluetooth mesh networking, Bluetooth Low Energy (BLE), Bluetooth 5G, and Wi-Fi

Word Count: 2140

Meta Description: Mastering Bluetooth PCB Technology: Our Guide to Seamless Connectivity. Learn the importance of Bluetooth PCBs in modern electronics, from wireless connectivity to energy efficiency. Explore future prospects and challenges. Stay ahead with evolving Bluetooth technology for a competitive edge.

—————————————————————————————————————-

In this guide, we’ll provide you with a comprehensive understanding of mastering Bluetooth PCB technology. You’ll discover what Bluetooth PCBs are, why they’re essential, where they excel, and how to optimize their performance. Whether you’re new to this technology or have prior experience, our goal is to empower you with a deeper comprehension of Bluetooth PCBs for achieving seamless connectivity.

Introduction

To Explore the significance of Bluetooth PCBs for seamless device communication in the dynamic tech landscape. Discover their definition, purpose, and vital role in electronics in this comprehensive guide.

- Definition and Purpose of Bluetooth PCB

Bluetooth PCBs, or Bluetooth Printed Circuit Boards, are specialized boards designed for wireless communication among electronic devices within a short range. Operating in the 2.4 GHz ISM band, they enable secure data exchange, audio streaming, and more. These boards eliminate the need for cables, enhancing mobility and versatility in device connections. They support Bluetooth standards like energy-efficient BLE, perfect for wearables and smart devices. In summary, Bluetooth PCBs enable wireless communication, enhance mobility, support various Bluetooth standards, including power-efficient BLE.

- Importance of Bluetooth PCB in Electronic Devices

Bluetooth PCB technology plays a vital role in electronic devices, transforming user experiences and driving innovation. It enables seamless connectivity, allowing gadgets to communicate effortlessly. The absence of wires enhances mobility and convenience, reducing clutter. Energy-efficient Bluetooth Low Energy (BLE) technology prolongs battery life in portable devices. Its universal compatibility ensures easy connections across various platforms. Bluetooth PCBs’ versatility extends to consumer electronics, healthcare, and industrial automation, making them indispensable in today’s world. Stay tuned for an in-depth exploration of Bluetooth PCBs in our comprehensive guide.

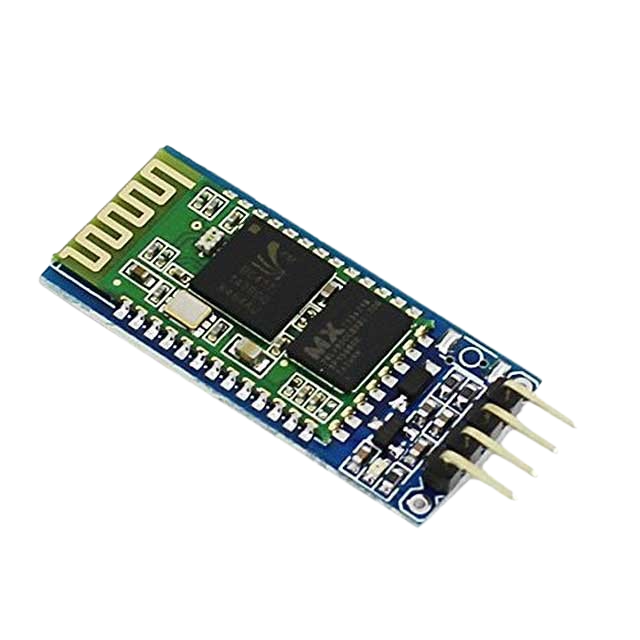

Figure 1: High-Density Interconnect Bluetooth PCB

Basics of Bluetooth Technology

- Overview of Bluetooth Technology

Discover the evolution of Bluetooth technology from its inception to modern standards like Bluetooth 5.0 and Bluetooth Low Energy (LE) in this comprehensive overview of wireless connectivity.

- Invention and Evolution

Bluetooth, pioneered by Ericsson in 1994, revolutionized wireless communication as a versatile alternative to RS-232 cables, becoming a widely used technology over time.

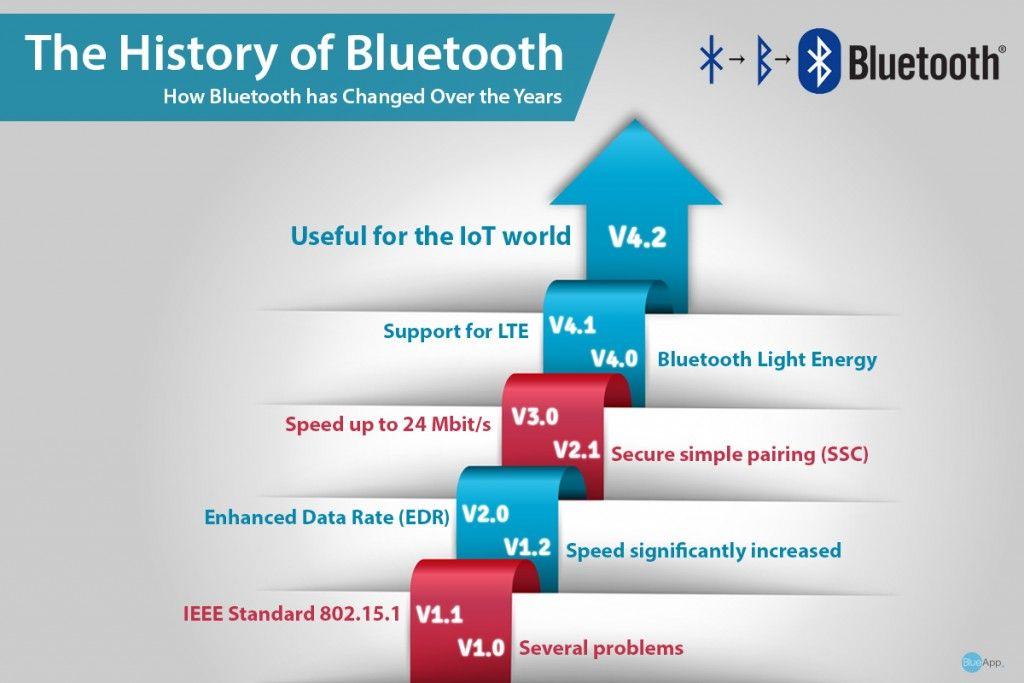

Bluetooth’s evolution can be divided into several generations, each introducing new features and improvements:

- Bluetooth 1.0:

The first generation, released in 1999, offered basic connectivity with a maximum data transfer rate of 1 Mbps.

- Bluetooth 2.0:

Introduced in 2004, this version enhanced data transfer speeds and introduced Enhanced Data Rate (EDR) technology.

- Bluetooth 3.0:

Released in 2009, Bluetooth 3.0 incorporated High-Speed (HS) technology, enabling faster data transfers.

- Bluetooth 4.0:

This version, introduced in 2010, marked a significant shift with the introduction of Bluetooth Low Energy (LE) technology, making it more energy-efficient and suitable for a wider range of applications.

- Bluetooth 5.0:

Released in 2016, Bluetooth 5.0 brought further enhancements, including increased range, higher data transfer rates, and improved coexistence with other wireless technologies.

Figure 2: Bluetooth Evolution

- Bluetooth 4 vs 5: Choosing the Right Version for Your Device

Bluetooth 5 offers faster data transfer rates, doubling from 1Mbps to 2Mbps compared to Bluetooth 4.2. It also boasts a significantly longer range, making it ideal for outdoor and indoor use. Additionally, Bluetooth 5 consumes less power, allowing for prolonged device usage. Its larger message capacity and compatibility with various versions make it suitable for IoT devices. Meanwhile, Bluetooth Classic is best for short-range data transfer and audio streaming, while Bluetooth Low Energy excels in low-power applications like smartwatches and IoT devices.

Figure 3: Bluetooth 4.0 Vs Bluetooth 5.0

- Bluetooth Standards (e.g., Bluetooth 5.0, Bluetooth LE):

Bluetooth standards, like Bluetooth 5.0 and Bluetooth Low Energy (LE), greatly impact device capabilities. Bluetooth 5.0 enhances range and speed, ideal for IoT and wireless audio, while Bluetooth LE excels in low-power applications for devices like fitness trackers and sensors.

- Role of PCB in Bluetooth Devices

Now that we have a solid understanding of Bluetooth technology, let’s delve into the crucial role that Printed Circuit Boards (PCBs) play in Bluetooth-enabled devices.

- Connection between Bluetooth Modules and PCB

Code:

| pinMode(GPIO_pin, OUTPUT);digitalWrite(GPIO_pin, HIGH or LOW); For input configuration:pinMode(GPIO_pin, INPUT); // Standard inputpinMode(GPIO_pin, INPUT_PULLUP); // With internal pull-up resistorpinMode(GPIO_pin, INPUT_PULLDOWN); // With internal pull-down resistor |

PCBs are the essential backbone of Bluetooth devices, enabling seamless integration of modules like transceivers and microcontrollers for reliable signal transmission.

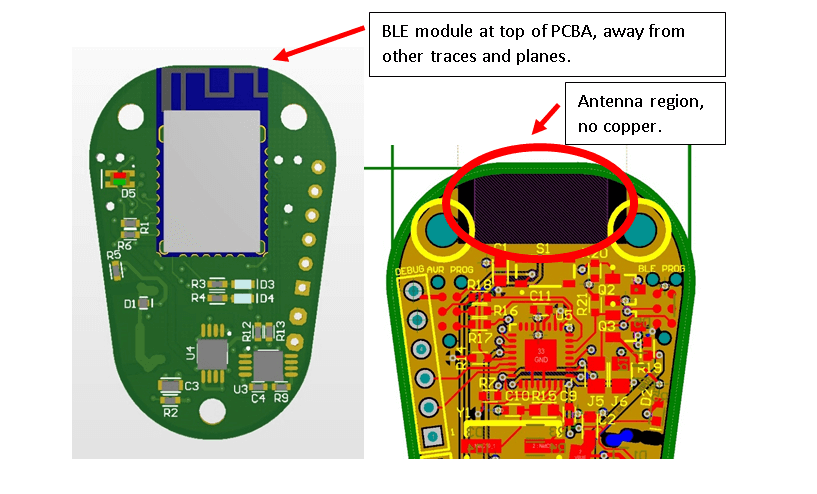

- Antenna Integration on PCB

Optimizing antenna integration on PCBs is crucial for Bluetooth technology, impacting signal range and performance. Consider antenna type, positioning, and impedance matching to ensure stable connections and seamless Bluetooth device connectivity. Stay informed about Bluetooth standards and PCB integration for superior Bluetooth-enabled product performance.

Figure 4:Bluetooth Technology with Antena Design and RF Layout

Components of a Bluetooth PCB

- Microcontroller Unit (MCU)

The Microcontroller Unit (MCU) serves as the core of a Bluetooth PCB, playing a pivotal role in data processing, Bluetooth stack management, power efficiency, user interface control, and security. Its significance lies in its ability to ensure seamless connectivity. When selecting an MCU, consider factors such as processing power, Bluetooth compatibility, power efficiency, memory capacity, and I/O interfaces to optimize your Bluetooth PCB’s performance and functionality.

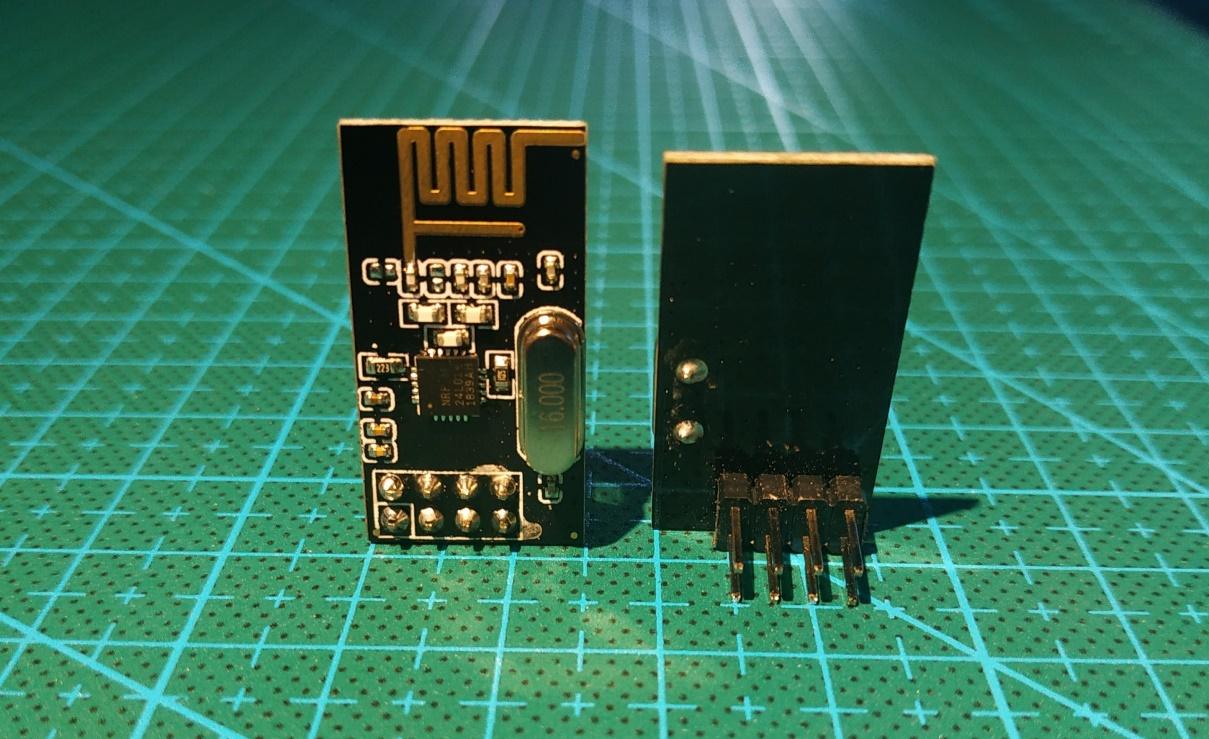

- Radio Frequency (RF) Module

- Understanding RF Modules

RF modules are essential components for Bluetooth PCBs, as they handle the wireless communication between devices. Here’s what you need to know about RF modules:

- Frequency Bands

- Transceiver Functionality

- Data Rate

- Compatibility

- Integration with PCB

Integrating the RF module with the PCB is a critical step. Follow these guidelines:

- Placement

- Antenna Connection

- Ground Plane

Figure 5: RF Module PCB

- Power Supply Section

- Voltage Regulators:

Voltage regulators ensure a stable and reliable power supply for the Bluetooth PCB. Here’s what you need to know:

Voltage regulators ensure stable power levels, safeguarding electronics, while high-efficiency models conserve energy for longer battery life in portable devices.

- Battery Management:

Proper battery management is crucial for Bluetooth PCBs, particularly in battery-operated devices:

- Battery Selection:

Choose the right battery type (e.g., Li-ion, LiPo) based on energy density, voltage, and form factor.

- Charging Circuitry:

Implement a charging circuit that safely charges the battery and prevents overcharging or over-discharging.

- Battery Monitoring:

Incorporate battery monitoring circuitry to provide accurate battery status information to users or the MCU.

- Antenna Design

- Antenna Types

Antennas play a pivotal role in Bluetooth connectivity. Consider these antenna types:

- PCB Trace Antenna

- Chip Antenna

- Antenna Placement on PCB

Proper antenna placement is essential for signal strength and range:

- Clearance

- Ground Plane

- Orientation

Mastering component selection and integration is crucial for successful Bluetooth devices, ensuring seamless and efficient communication.

PCB Design Considerations

In this section, we’ll delve into key considerations for designing your Bluetooth PCB.

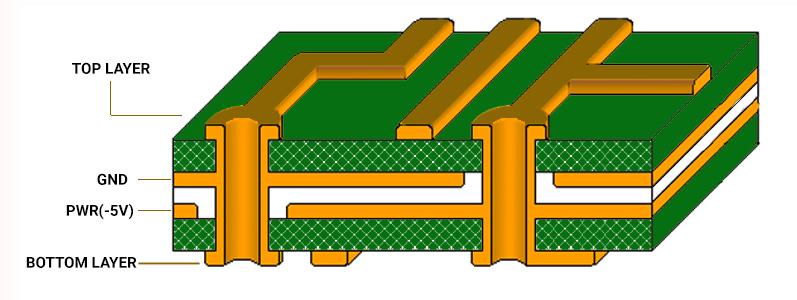

Figure 5: Bluetooth PCB Design Consideration

- PCB Layout

Optimizing PCB Design for Bluetooth Devices: Importance of Layer Stackup and Trace Routing. A four-layer stackup layout or eight-layer stackup layout enhances signal integrity, while short, well-routed traces reduce interference for high-frequency Bluetooth signals.

Figure 6: 4-layer PCB Stackup

- Noise and Interference

To minimize EMI/RFI in Bluetooth devices operating in the 2.4 GHz ISM band, employ shielding techniques like ground planes and RF chokes. Implement a star grounding system to reduce interference and ground loops.

Figure 7:Noise and Interference Control

- Size and Form Factor

Boost Wearable and IoT Device Efficiency with Compact PCB Designs, Surface-Mount Components, and Rigid-Flex PCBs for Enhanced Portability and User Experience.

- Cost Efficiency

To ensure Bluetooth product success, strike a balance between features and costs, aligning with your target market. Factor in component availability, assembly complexity, and design impact on production costs.

To excel in Bluetooth PCB technology, prioritize PCB layout, noise reduction, size, cost, and form factor for reliable connectivity and successful product launch. Adhering to these design principles ensures optimal Bluetooth device performance in today’s connected world.

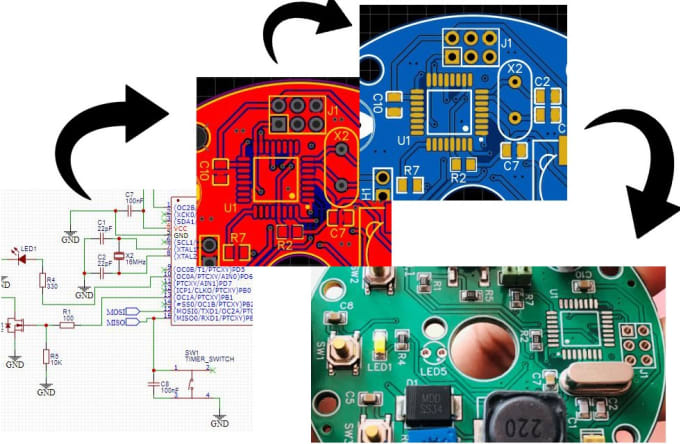

Prototyping and Manufacturing Bluetooth PCBs

In this section of our comprehensive guide, we will explore the various prototyping and manufacturing methods, as well as testing and quality control processes that can help you master Bluetooth PCB technology.

- PCB Prototyping Methods

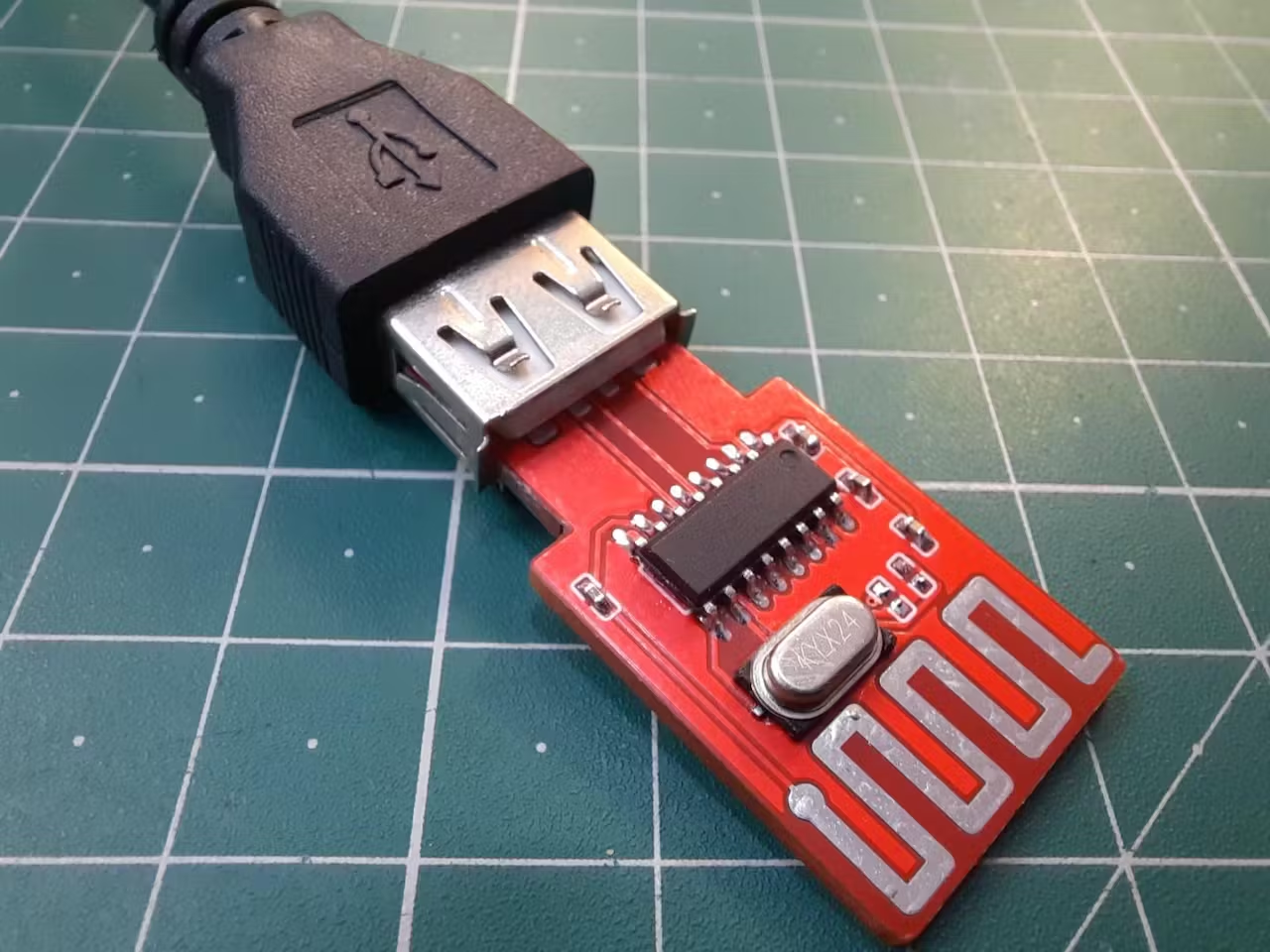

- DIY Prototyping

DIY Bluetooth PCB prototyping offers cost-effective flexibility for tech enthusiasts, fostering a valuable learning experience.

- Professional Prototyping Services

Professional prototyping services provide high precision and speed using advanced equipment for complex projects, ensuring top-notch quality.

Figure 8: PCB Prototyping of Bluetooth Technology

- PCB Manufacturing Processes

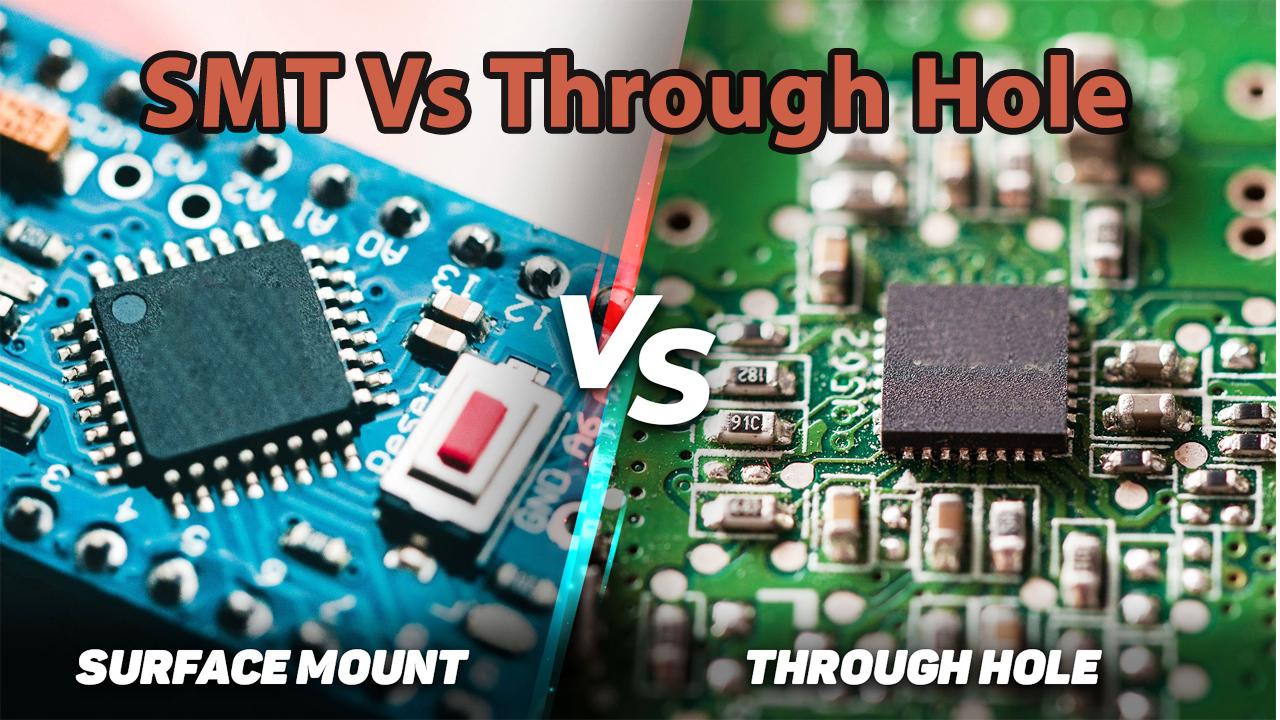

- Surface Mount Technology (SMT)

Surface Mount Technology (SMT) is a widely-used manufacturing process for Bluetooth PCBs. Here’s why it’s favored by many:

- Compact Design

- High Density

- Automated Production

- Through-Hole Technology (THT)

Though not as common as SMT for Bluetooth PCBs, Through-Hole Technology (THT) still has its applications. Consider these aspects:

- Durability

- Repairability

- Mixing Methods

Figure 9: SMT VS THT

- Testing and Quality Control

Functional testing is crucial for ensuring Bluetooth PCB performance by identifying and resolving connectivity issues, maintaining product quality, and enhancing customer satisfaction. FCC certification is essential for legal compliance, market access, and interference mitigation in the Bluetooth PCB industry.

Mastering Bluetooth PCB technology demands a strategic blend of prototyping, manufacturing, and testing, whether via DIY or professional services, SMT or THT methods, all aimed at achieving flawless Bluetooth connectivity for your devices.

Figure 10:DIY USB Bluetooth 3.0 PCB For Car Amplifier

Bluetooth PCB Applications

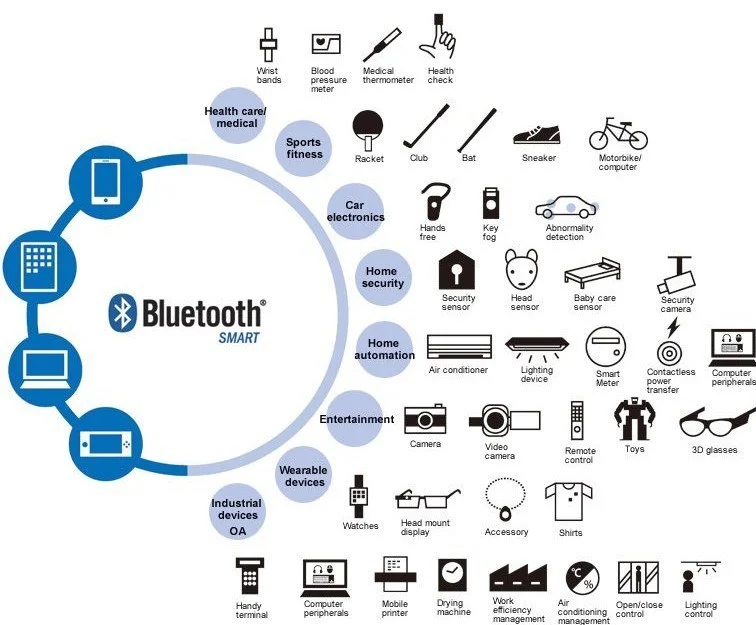

In this section, we will explore various applications of Bluetooth PCB technology, showcasing its versatility and impact across different industries.

- Consumer Electronics

Bluetooth technology is integral to modern smartphones, enabling wireless functions like file sharing and audio streaming via Bluetooth PCBs. Wireless Bluetooth earphone pcb and speakers also leverage Bluetooth PCBs for convenient, cordless audio experiences, gaining widespread popularity.

- IoT Devices

Bluetooth PCBs power Smart Home IoT devices for remote control and efficiency, while Wearables use Bluetooth to provide health insights via data transmission.

- Industrial and Automotive

Bluetooth PCB technology enhances automotive infotainment systems for hands-free connectivity and vehicle improvements, while also optimizing industrial IoT devices for machinery control and process optimization.

Figure 11: Bluetooth Applications

Future Trends and Advancements

Explore the future trends and advancements in Bluetooth PCB technology, redefining wireless connectivity in our comprehensive guide’s final section. Stay ahead of the curve with insights into emerging developments.

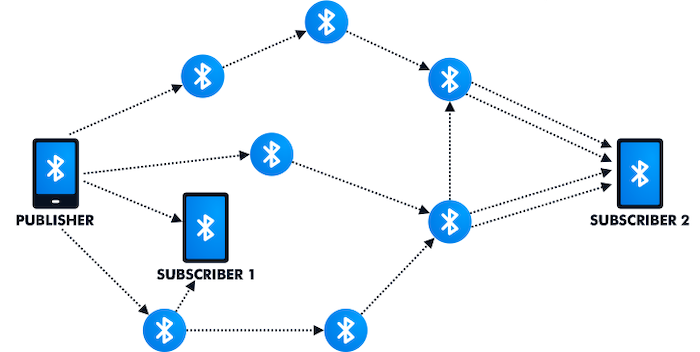

- Bluetooth Mesh Networking

Bluetooth Mesh Networking: A Game-Changer for Interconnected Devices, Enabling Smart Homes, Cities, and Industries with Self-Healing, Self-Optimizing Capabilities.

Figure 12:Bluetooth Mesh Networking

- Bluetooth Low Energy (BLE) Improvements

BLE technology revolutionizes Bluetooth with energy-efficient, long-lasting connections. Future advancements promise extended battery life for wearables, healthcare sensors, and asset tracking.

Figure 13: BLE Technology

Explore Bluetooth Low Energy (BLE): History, Applications, and Future Trends

As the demand for low-power wireless communication solutions grows in our interconnected world, Bluetooth Low Energy (BLE) emerges as a vital IoT technology. This article delves into BLE’s history, development, and its diverse applications in healthcare, fitness, home automation, automotive, and location-based services. While BLE offers efficiency, security concerns and limited data transfer rates are challenges. Looking ahead, AI integration, Bluetooth specification advancements, energy harvesting, and BLE-5G convergence promise to shape the future of wireless communication, making BLE a crucial player in the evolving IoT landscape.

Figure 14:Bluetooth Low Energy (BLE) Applications

- Integration with 5G and Wi-Fi

The convergence of Bluetooth technology with 5G and Wi-Fi is a significant step towards a seamless connectivity ecosystem. This integration will enable devices to intelligently switch between these wireless technologies, ensuring the most reliable and efficient connection at all times. The synergy between Bluetooth, 5G, and Wi-Fi will accelerate the development of IoT applications, smart infrastructure, and immersive experiences.

Figure 15:Bluetooth technology with 5G and Wi-Fi

Embrace evolving Bluetooth PCB technology for a brighter wireless future. Stay ahead in innovation and enhance products with these trends. Position your business at the forefront of the connected world by adopting Bluetooth advancements. Elevate your services through the power of wireless connectivity. Explore the exciting possibilities of Bluetooth for a competitive edge.

Figure 16:Evolving Bluetooth PCB technology

Importance of Bluetooth PCB in Modern Electronics

Bluetooth PCB technology has become indispensable in modern electronics. Its significance is highlighted by several key factors:

- Wireless Connectivity

- IoT Revolution

- Energy Efficiency

- Cross-Platform Compatibility

- User Convenience

Future Prospects and Challenges

As we look ahead, the world of Bluetooth PCB technology continues to evolve. Here are some future prospects and challenges:

- 5G Integration

- Enhanced Security

- Low-Power Innovations

- Interoperability

- Environmental Sustainability

Conclusion

Master Bluetooth PCB technology with our comprehensive guide, exploring seamless connectivity in modern electronics. Learn Bluetooth basics, PCB design, regulatory compliance, and security. Discover the importance of Bluetooth PCBs in wireless connectivity, IoT, energy efficiency, and cross-platform compatibility. Explore future prospects like 5G integration, enhanced security, low-power innovations, interoperability, and environmental sustainability. As Bluetooth PCBs evolve, they remain pivotal in shaping modern electronics, offering limitless possibilities for innovation and convenience.